Explaining the Race Case System – Part 1

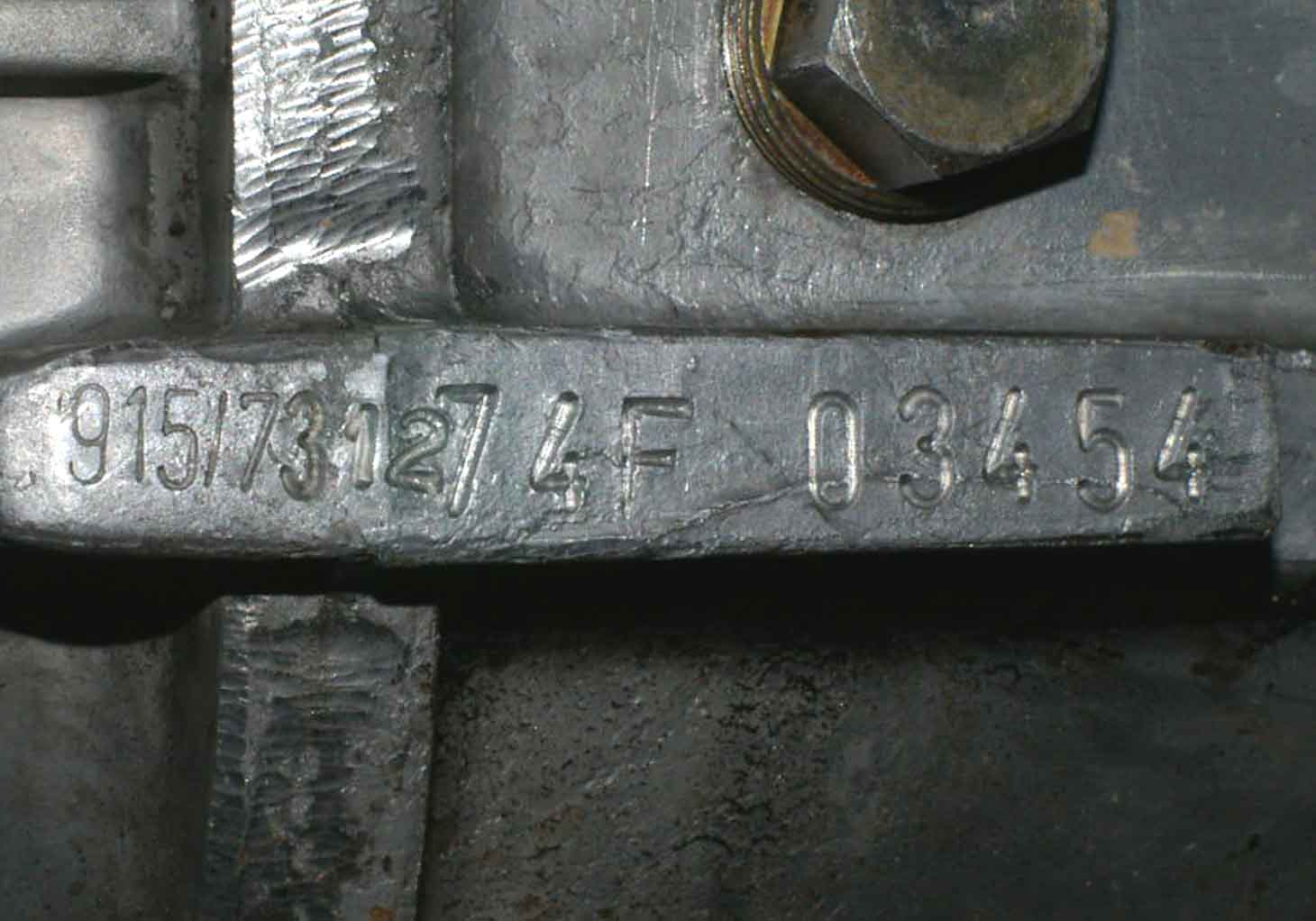

The Race Case System is one of the many 915 upgrade products we have developed at WEVO. This system allows for otherwise scrap 915 transmission cases to be remediated and returned to service in better than new condition.

The most recent new 915 delivery from Porsche was in 1986, some 24 years ago! With the 915 used in such great high mileage road warriors as the 911SC and 3.2 Carrera, we see transmissions that have been used (and abused!) in a way that is well beyond the test conditions originally explored by the factory.

By Porsche enthusiasts globally, the 915 transmission (“nine-fifteen” in the USA or “nine, one, five” in English speaking nations) has become loved for it’s lightweight, simplicity, broad model year application by Porsche and suitability for track work. Having said that – there are several accepted weaknesses in the 915, here I will focus only on how the transmission casings themselves are re-worked by WEVO to revitalize them for an ongoing future.

I covered some amazingly dodgy efforts to cure this issue on an earlier blog post. Sad and ignorant work performed at the expense of an uninformed customer.

The core issue with 915 transmission cases is the location and fit of the shaft bearings. The 915 contains 6 primary shaft bearings, 4 roller bearings and 2 thrust bearing. The 4 roller bearings are press fit into their location – arranged with two bearings carrying each of the input (main) shaft and pinion shaft. The location dowels on the case joint faces in conjunction with the accurate location of the bores and perpendicularity of the case faces are key to these shaft bearings being arranged in parallel and co-axial. Mileage, heat, lubrication and abuse all lead to a loss of the intended bearing arrangement, then exacerbating the worn condition and further reducing the performance of the transmission – a degradation spiral.

SOME 915 HISTORY AND COMMENTARY;

As a generalization I can say that the Porsche 915 pressure castings are beautifully machined pieces with very high accuracy. This is a real testament to the manufacturing efforts of Porsche as a small volume manufacturer. To put his in context, in 1972 when the 915 was first introduced, Porsche delivered a combined total of 911T, E and S models ~ 6000 cars. This equates to just 25 transmissions per day for the production year.

From 1972 to mid 1977, the Magnesium alloy 915 transmissions were manufactured with a cast steel insert, co-cast in the location of the pinion bulkhead bearings of the final drive housing. This created a durable precision armature to manage the location and fit of the pinion bearings. The roller bearings are installed directly into this steel insert.

During 1977 the effects of a corporate technical mandate that initiated from research in the Porsche Motorsports division, lead to the replacement of all Magnesium alloy components with more durable Aluminium alloy parts. This was particularly evident in the pressure cast casings for the 915 transmission and the engine crankcases.

From mid 1977 the Aluminum alloy case 915′s prevailed. The steel insert was no longer co-cast in the pinion bulkhead of the final drive housing – the roller bearings were now installed directly into the aluminum bores in the housing.

From 1984 and the introduction of the Carrera 3.2 motor, the 915 final drive housing was altered to accommodate a small OD roller bearing where the input shaft is carried in the pinion bulkhead of the final drive casing. This 55mm Ø bearing (930 302 391 00) is taken directly from the 930 series transmission. The smaller OD allowed for the narrow bridge of material between the two bearings to increase in cross section by about 300% – I presume in an effort to improve stability of the bearing bores in this particular area. The previous 62mm Ø bearing (999 110 032 00) rarely shows any sign of problem, underwriting my opinion that the smaller and more expensive 930 bearing is a packaging decision related to the integrity of the roller bearing fit.

There were other subtle variations to the casings, such as the mounting of the clutch guide tube, the input shaft seal, shift rod bearings, speedometer provisions etc. - all interesting – but for another expose.