Career Guidance – Formula SAE

January 17th, 2010In April of 2009 when Tracey and I were on a brief visit to Australia, I had the opportunity to visit the ECU Motorsports workshops at Joondalup and talk with half a dozen of the ECU, Formula SAE team who were completing the 3rd year of the ECU Bachelor of Technology (Motorsports) course that uses the FSAE platform for assessment.

I offered as much hard nosed pragmatism as I though the 3rd year greenhorns would listen to, then added WEVO to the sponsor roster for the 2009 ECU FSAE challenge. With such easy access to the myriad of Aircraft fastener systems from our WEVO office in California, it seemed appropriate to assist the team with sponsorship of their fastener and bodywork fastener requirement (thanks to Coast Fabrication, CAÂ and Skybolt, FL).

Windrush Yachts in O’Connor, WA has been a sponsor of both ECU and the 2008 World Champions UWA over the past several years. Tracey and I were happy to add WEVO and our contributions to the efforts of students in the most remote city in the world – Perth, Western Australia.

When I was studying at Curtin university in the early 80′s no such career education opportunity existed, if you had a passion for a vocation in motorsports, then it meant completing a Degree in an associated field (in my case Industrial Design) then travel abroad in an effort to make friends and forge an opportunity…… pretty wildcard, but hundreds of Western Australians before me went on the same path, with many – like Kim and Barry Green making it all the way to the top of ladder in the USA.

In 2009 the FSAE – Australasia was contested by 24 teams from Australia and New Zealand, around the globe the number of teams participating in FSAE is over 200. It provides a wonderful environment for our youngest creative thinkers to explore the rules of the FSAE and be exposed to the learning and the pain of learning in a truly unique manner. There is no doubt the FSAE and the tertiary programmes that employ the FSAE as a key part of the curriculum are producing some fine young engineers and technicians to fill the openings in the motorsports industry. In addition, these young men and women are exposed to unique design, fabrication and project management challenges that make their experience appropriate for many other problem solving industries too.

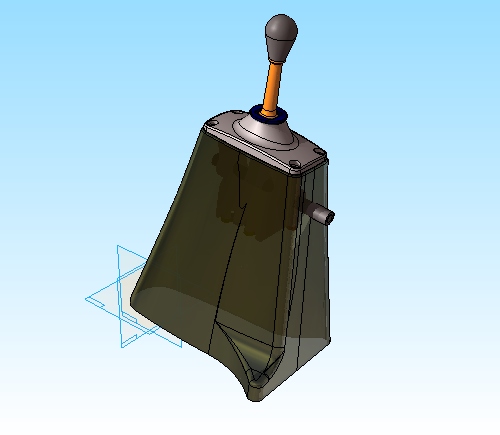

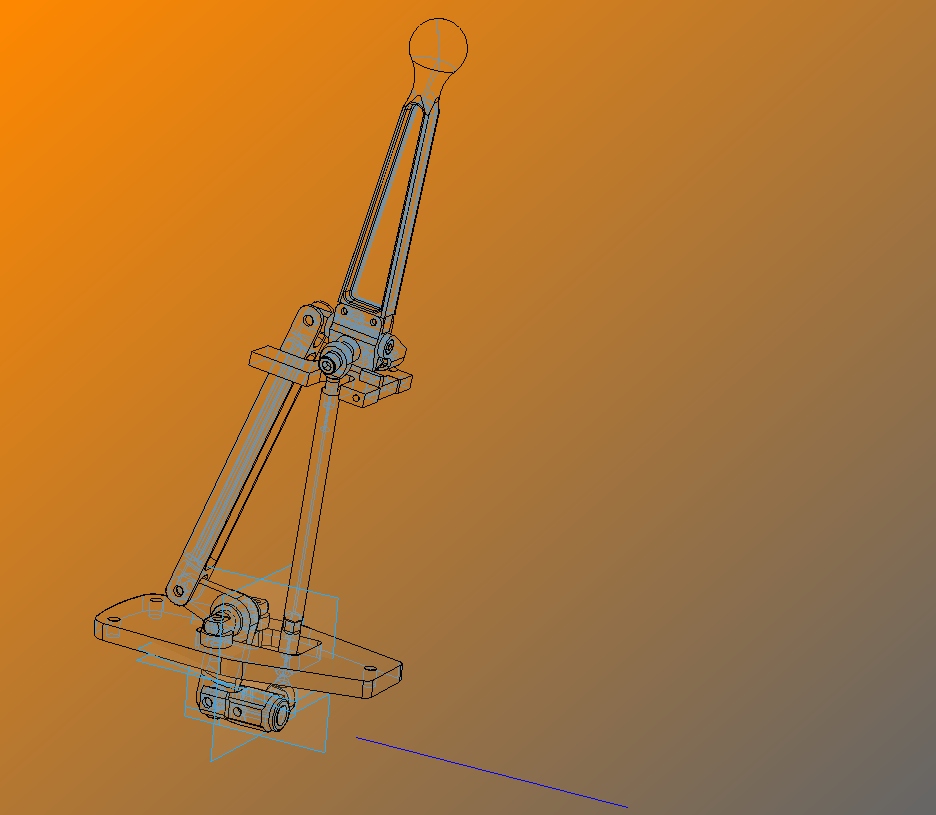

Last week, on another trip to Perth, I caught up with John Hurney, course controller, Luke Mason Team Principal and James Murdoch - lead on Chassis design. Luke and James showed me the variety of solutions they had designed since my visit in May and were clearly massively more mature from the whole experience. They were both filled with stories from the 2009 run-off event experience in Melbourne too, where the ECU teamed finished a credible 6th place in only the second year of participation. The FSAE has been a large part of their last 12 months – obsessively large and will be an experience that will serve to remind them over and over the fundamantals of completing and managing projects of this style.

Good luck to the 2009 graduates of the ECU Motorsports programme, hopefully the efforts by all the local sponsors, mentors, tutors and lecturers will help you reach your own goals in a motorsports career without ever needing to experience the “old fashioned way”